By Lauren Wiles, John Muncaster © 2023, Goldratt UK

It has been a very difficult few years for the UK’s manufacturing industry and unfortunately there are still challenges ahead. MakeUK and PwC conducted a survey of over 200 senior manufacturing leaders which revealed that almost three-quarters of companies (70%) expect their energy costs to increase this year, with two-thirds expecting to cut production or jobs as a result. Stephen Phipson CBE (Chief Executive, MakeUK) summarises that “the biggest risk [to UK manufacturers] remains the eye watering increases in energy costs which has left the clock ticking for many companies.”

Though the resilience of UK manufacturing is being tested once more, there are still options management teams should consider to best control costs and weather the storm that is the energy crisis.

1.Make Sure Any Improvement is Directed Towards the Constraint (Bottleneck)

Goldratt’s Five Focusing Steps provide a helpful guideline for structuring improvement:

- Identify the Constraint.

- Exploit the Constraint.

- Subordinate to the Constraint.

- Elevate the Constraint.

- Go back to Step One – Prevent Inertia.

The first step is always to ‘Identify the Constraint’ (or bottleneck). During periods of high cost, the Constraint of your business will be cash. So, you must treat it in the same way you treat any constrained resource – you must exploit it.

According to recent stats from CB Insights, cash flow is the biggest cause of UK business failure – 38% of failed businesses ran out of cash or failed to get the required capital. The key to ensuring good cash flow is to keep the cash-to-cash cycle as short as possible. Producing and delivering finished goods to customers – as quickly as possible – is the fastest way to get money into the business

For more information on how you can identify your system’s Constraint, you can read our previous blog post here. One helpful hint would be to look at where you repeatedly see queues materialise… this is a good guide to which operation struggles to keep up with the demand.

It is important to invest in the right place at the right time. If cash is your Constraint, then you need to be investing time, money, or both in ways that will decrease the cash to cash cycle. Essentially reducing the amount of time your cash is tied up in making your product.

If it is the case that you have more orders than you can cope with, and you are looking to shorten your production lead-times and get more goods out the door to customers quicker (get your expenditure turned to revenue as quickly as possible), you must now identify your Constraint within Operations. Work can only progress through your system as fast as the Constraint can process it – it dictates the rate of flow through your entire plant. This is where you should direct improvement first. Any improvement to your Constraint – no matter how small – will always be more valuable than an improvement made to a non-bottleneck.

The risk you face when you improve a non-bottleneck operation, especially one which sits before the Constraint in the process, is increased queues of WIP (which means your money sits and queues for longer in your plant). Naturally, if one operation produces much higher output than a capacity constrained resource, the latter will never keep up. Queues of work will constantly sit in front of it compromising visibility and creating opportunity for mistakes to creep in (working on the wrong job for example). This will only increase the risk of longer lead-times; this would mean a longer wait until the company makes money on the product.

Improve your Constraint area first, then when you have increased the output of the bottleneck, you can look for your next one (if a new one emerges). Alternatively, you may be in a situation where you have less orders to satisfy, in this case you only need to activate the bottleneck enough to produce what is required; activating it more than is required would only consume cash (using power and material you don’t need). Controversially, it may be necessary to make your bottleneck less efficient by running smaller batches to avoid needlessly consuming cash (more on this later!).

2. Don’t Cut Capacity in Areas You Appear to Have Excess…

It is a common assumption among manufacturers that they can balance all their capabilities, but this is rarely true. This is only a possibility in a one-piece flow, which most companies do not have. More likely, your business will have resources where on average, demand remains low.

In the point above we mentioned how work can only progress through your system as fast as the bottleneck operation can process it, and we touched on the need to keep WIP low to avoid queues. We would recommend you limit the release of work at the front end to limit queues of WIP and reduce lead-times – this will contribute to a shorter cash-to-cash cycle. However, in doing so you will find non-bottlenecks with excess capacity; the solution is not to simply cut this capacity to reduce costs.

Whilst demand on average may be low, there may be sudden surges to ensure synchronisation with other resources – you must be able to meet this demand. Failure to do so could mean other resources are starved of work and therefore delays occur. This surge in demand could be very high for short periods of time but it’s essential to reserve capacity to cover it in order to avoid overall delays.

This is especially important when it concerns the bottleneck in environments where there are more orders than capacity to deliver. The second of Goldratt’s Five Focusing Steps is to ‘Exploit the Constraint’. It is important to have your Constraint as close to 100% capacity as possible. This means there should always be a buffer of work available in front of it. If you cut capacity at the front-end, you run the risk of starving the Constraint. Every second your bottleneck operation is not working; your business loses money. To starve it of work due to cost cutting in other areas would be a mistake. Furthermore, having excess resource in non-bottleneck areas does not mean they have to stand idle. You now have the ability to direct those resources toward rising queues and maintain good visibility of WIP throughout the system.

3. Look at Switching to Local Suppliers

Switching to local suppliers may not always be an option, but if you can source materials locally you are faced with a fantastic opportunity to free up cash! As energy prices continue to rise, improving your company’s cash flow could mark the difference between your company ticking over or shutting its doors.

Whilst sourcing materials and manufacturing in low-cost economies appears to have the benefit of reducing business costs, that is not always the reality. In fact, you could be losing money in the long run… When cash is tight, it is important to spend it on the things you need now as opposed to things you might need in ten years’ time!

The long lead-times necessary to deliver from the Far East means you will need to order enough inventory to tide you over until your next delivery arrives. At best this means your money is tied up in inventory you will use in a couple of months’ time – at worst you could have your money tied up in stock AND be paying out for additional storage space to keep it… This would cancel out any cost saving your Purchasing Department made buying from a country where purchase prices are cheaper.

Even if your forecasts are completely accurate (unfortunately unlikely…) and you can predict the precise volume of stock you will need to cover your sales orders during the delivery time, you will likely find that you still have to stock larger amounts of inventory than you need. This is due to the Minimum Order Quantities businesses in the Far East enforce. Per item you’ll get a discount… but the wider cost implications are not always worth it.

The benefit of switching to local suppliers means you can receive more frequent deliveries; this allows you to better deliver on any unexpected surges in sales, and saves you space. You may have an opportunity to make some significant cost reductions by reducing the need for any third-party warehouse space.

For further explanation, we have offered our opinion on the age-old debate around local vs. global suppliers – you can read it here.

4. Optimise Your Warehouse Space

Whilst we are on the subject of storage costs, here’s a further suggestion for how you can reduce them. If you utilise third-party storage, optimising your own warehouse space could be the solution. Make sure you are not paying out unnecessarily…

As highlighted in the point above, you can switch to local suppliers for more frequent deliveries of materials – this reduces your need to store large volumes of inventory.

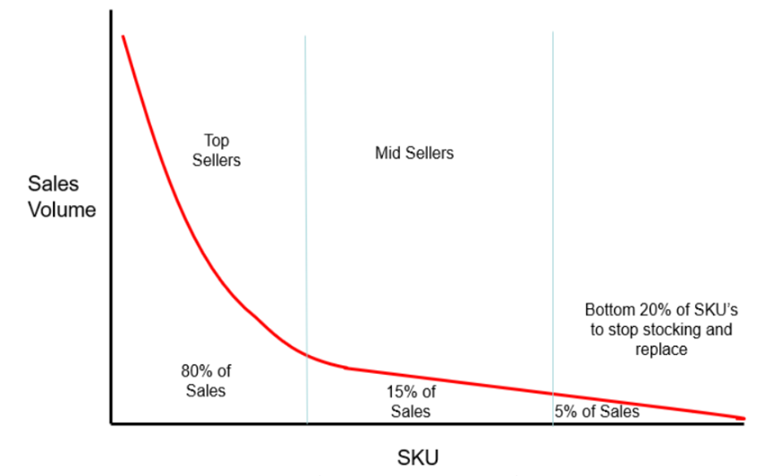

Another option is to assess your range. Typically, when looking at different business’ ranges, you can expect to find that roughly 80% of their sales come from only 20% (or less…) of their product range. You can divide your range up into a head, body, tail.

The ‘tail’ equates to very low levels of sales but still consists of many SKUs that business’ think they need to offer the market a full range. These are the products where the sales volume and frequency are low, yet they are still being stocked and reordered. The policy here is straight forward: identify them and get rid! Identify these products and implement a plan to remove them – free the space, free your cash.

For a more detailed understanding of Range Management, you can read this article.

5. Produce in Smaller Batch Sizes – Don’t Waste Energy on Products You Aren’t Going to Sell

We touched on this situation a little at the end of point 1, now let’s expand.

Manufacturing organisations have always faced the same dilemma over what is the appropriate batch quantity to manufacture – Minimum Order Quantity/Economic Batch Quantity vs. quantities that match customer orders.

From an efficiency/productivity perspective, bigger batches seem to make sense. To maintain high output, your team wants to avoid chopping and changing equipment with different setup times etc. – it’s more efficient to run bigger batches. Efficiency indicates that neither time nor energy is being wasted. This must be the best move then, right? Maybe not.

Given that rising energy bills are a pressing concern, you certainly don’t want to be wasting that energy producing stock you don’t need! If you stick to only making what you need, you will prevent overusing gas or electricity. Plus, you won’t have to worry about any further storage costs you may incur…

For an article weighing up big batches vs. small batches, you can click here. Understand the conflicting needs at play and determine which option is best suited to your environment.

Goldratt UK has worked implementing the Theory of Constraints in hundreds of Manufacturing and Warehousing environments across the United Kingdom and Europe. They have achieved impressive results.

If you have any questions regarding any of the topics covered in this article, or have any immediate challenges you need to address promptly, we can put you in touch with one of our industry experts for a free, no obligation call – email [email protected] to arrange a time.